- By Dan Veaner

- News

Print

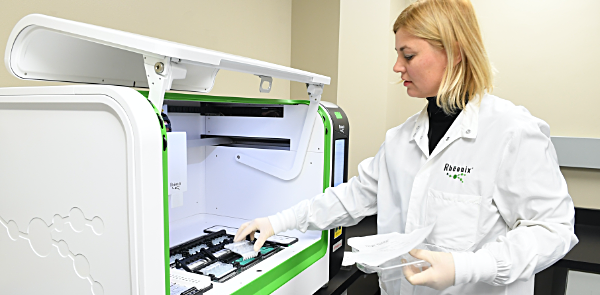

Print  Rheonix Senior Regulatory Specialist Daniela Bocioaga, Ph.D. loading an Encompass workstation

Rheonix Senior Regulatory Specialist Daniela Bocioaga, Ph.D. loading an Encompass workstation What if you could handle every COVID-19 test in Tompkins County using a couple of machines that look like giant microwave ovens. And what if you could load the devices and walk away until the tests are done, only four hours later? And what if the samples were self-contained within the machines and automatically destroyed after tests complete, leaving the biological waste remains in a disposable cartridge so technicians are not exposed to the coronavirus? And what if the tests were lower cost than the current testing procedures? And what if local health departments and hospitals could have the machines on-site, eliminating the time and cost to transport test samples out of town?

That's what scientists at Rheonix, Inc., a company in the Village of Lansing, asked themselves when they began developing a test kit for their Encompass MDx® workstation about a month ago. When the device was put on the market about three years ago it was used to detect spoilage organisms in beer during the brewing process, and since has been used for other kinds of food safety testing. But the machine can also be used for medical testing, and the company has spent the past four years going through the process with the US Food & Drug Administration (FDA) to get the machine certified to test for sexually transmitted diseases. But with the pandemic quickly reaching crisis proportions, the FDA has instituted Emergency Use Authorization (EUA) procedures that may mean the Rheonix device could be certified for use as early as next week.

"We are targeting being done with collecting the data we need for the coronavirus by this weekend and submitting early next week," says Rheonix CEO and President Greg Galvin. "And those, they have been tending to turn around in about 24 hours or less."

Galvin, a Lansing resident, founded Rheonix in 2008 to develop technology that would automate molecular testing. The company employs around 50 people at two locations in the Cornell Business & Technology Park near the airport. Around 12 to 15 of those jobs are development jobs, and about the same number manufactures the machines. Galvin says that the majority of his employees are involved in making the coronavirus test kit a reality.

The company's Encompass workstations aren't that different in concept from your home computer printer. You load cartridges and software to run it, send it a job to do, and do something else while it is completing its task.

About 180 tests per day are currently being sent to state labs from Tompkins County. Galvin says that each workstation can process 120 COVID-19 tests per day. That means that two machines located at the Tompkins County Health Department or Cayuga Medical Center could easily process all the tests in the county with no backlog.

That could mean people who test negative for COVID-19 getting out of quarantine the next day, rather than waiting two weeks or however long it takes to get tests back from labs elsewhere in the state, not to mention taking some of the pressure off of those labs.

Testing for COVID-19 uses a Polymerase Chain Reaction (PCR) to 'amplify' the sample taken from your test swab. In the case of the coronavirus, it means very quickly making millions of copies of a piece of RNA so there is enough genetic material to be able to positively identify the virus if it is present. The machine automatically mixes the clinical samples with substances that react with the samples to detect the virus if it is present. Molecular genetic tests tend to have a very high accuracy rate.

"The thing with molecular diagnostics is, and why they're so attractive, is they're really, really accurate," Galvin says. "Essentially the genetic material you're looking for is present and if you correctly designed the genetic sequence such that you're targeting the right thing, it's binary. If it's there, you see it. If it's not there, you don't see it. The genetic tests and molecular tests tend to have a 98-plus percent accuracy."

While the Encompass machine doesn't change, the particular assay, or test kit used with it is specific to a particular pathogen. It includes the chemicals and software that tell the machine exactly how to conduct a test. Bar coded collection tubes are placed in a cartridge, which is then inserted into the workstation, so the technician has no exposure to the samples. He or she can walk away, and four hours later the test results are displayed on the workstation screen and may be uploaded to review later.

"There are small variants in the software used to run it, that says how many cycles through the PCR do I want to do, and at what temperatures," Galvin explains. "There are subtle things that do get tweaked for the particular asset, but predominantly the guts of it is, it's the chemicals that are being used, particularly what are called the primer probe pairs, which are the pieces of genetic material that you're targeting and using to do the amplification. So the things that are unique to the pathogen of interest."

Galvin notes that the assay dor detecting sexually transmitted infection, plus it's clinical trials and the 1500 page case submission was four years in the making and still pending. Contrast that to the virtually overnight 'emergency use authorization' approval process, and you get an idea of just how serious the FDA considersCOVID-19 to be. Galvin adds that the stereotype of government bureaucrats and that anything the government does is slow, slow, slow... doesn't reflect his experience at all.

"Working with the FDA 'worker bees' has just been phenomenally impressive," he says. "These guys are answering emails 24/7. I mean, Sundays... it doesn't matter. They are very responsive."

Galvin says that being able to create a solution to such a universal threat in a short period of time has created a lot of excitement within his company. The 'assay' is being tested with deactivated coronavirus samples, and Galvin says Rheonix's EUA application should be ready for submission early next week. That could put the equipment in service within days.

"It's a very strange feeling to feel something positive in the middle of a pandemic, but this opportunity and need has really incentivized everyone," Galvin says. "People are working really hard and we're seeing things accomplished at a pace that we've never seen before, in part helped by the government doing whatever it can to expedite approvals and relax rules. It's very motivating to see something come together in a matter of weeks and actually have very strong interest from the regional hospitals in getting their hands on it as soon as we have approval to let them do so."

v16i14