- By Dan Veaner

- Around Town

Print

Print  Cargill Deicing Technology (CDT) offered dinner and information to neighbors last week to explain a new 2,500 foot deep mine shaft planned for a property near the intersection of Ridge and Sweazey Roads. Mine Manager Russ Givens told nearly 30 residents that the new shaft will allow the mine to remain productive and competitive in the long term future. While neighbors expressed concerns, Givens said the company intends to do what it can to minimize the impact.

Cargill Deicing Technology (CDT) offered dinner and information to neighbors last week to explain a new 2,500 foot deep mine shaft planned for a property near the intersection of Ridge and Sweazey Roads. Mine Manager Russ Givens told nearly 30 residents that the new shaft will allow the mine to remain productive and competitive in the long term future. While neighbors expressed concerns, Givens said the company intends to do what it can to minimize the impact."This is the kick-off meeting to meet with the neighborhood," said Cargill's Ryan Weese. "We want to make sure they feel comfortable with what we're doing and why we're doing it, and to answer any questions they might have."

The Cayuga Salt Mine is the deepest and oldest of two salt mines currently operating in the state of New York. The mine is capable of producing over 2.1 million metric tons annually. Mining began in 1923, focusing on four levels of salt. Cargill purchased the mine in 1970, transforming a rail system for transporting the salt to a conveyor belt system.

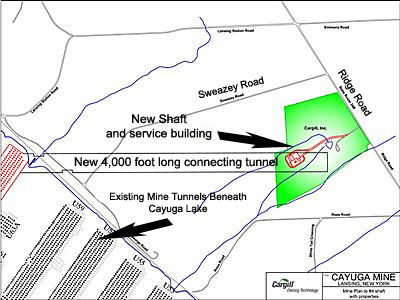

Active mining is entirely below Cayuga Lake, spanning from the topside Portland Point facility under the lake to as far north as Bill George Road near Swayze Road. Currently held mining rights will allow Cargill to expand farther north to Milliken Station before negotiating with the State again for more area.

"By 2017 our operations will be far enough up the lake that without doing this we're going to have to reduce our productivity, either in the form of crews or output of the mine," Givens said. "This is because we won't have enough air to support the mine. At that point we'll have some significant electricity issues. By 2020 those northernmost reserves of the mine will be too far away to meet our regulations for mine evacuations. By law we have to be able to empty that mine in an hour or less."

Currently all air, electricity, equipment and manpower must descend through a shaft at the Portland Point location, then travel miles north to active mining areas. Givens says the main reasons for a more northern-located shaft are to get personnel into and out of the mine faster and to provide essential air and electrical power.

He says the company hopes to build and use it in a way that is least disruptive to neighbors. He noted that there are no plans to move Cargill's surface plant to a new location, so the salt will continue to be brought south to the Portland Point shaft to be removed from the mine and stored at the existing facility. He said it would cost the company $100 million to move the surface plant.

A stratigraphic 2,500 foot deep test hole is scheduled to be bored between now and early 2013 that will determine how the shaft will be drilled. Givens says that if no natural gas or water is encountered the company prefers to drill the shaft from the bottom up in the same manner as shaft number three at Cargill's Portland Point headquarters was drilled in 1976. Otherwise it will be drilled from the top down.

Meanwhile, a 4,000 foot long shaft will have to be mined from an existing tunnel to a location at the bottom of the proposed mine shaft. Givens says it will take about two years to complete the new tunnel. He said the impact of that excavation on neighbors will not be different than it has been when Cargill mines near their homes under the eastern side of the lake.

http://www.cargill.com/products/salt/winter/cayuga-salt-mine/

http://www.cargill.com/products/salt/winter/cayuga-salt-mine/The company bought a 57 acre plot of land. Because the property is crater-like the shaft and accompanying service building is not expected to be visible to neighbors, especially when the leaves are on the trees. Power lines and air fans will be part of the new construction. The shaft tower with a small hoist for an elevator to transport personnel and limited material will be approximately 75 feet tall, but Givens says it will be barely visible because there is a 60 to 80 foot drop-off on the property, and 20 foot tall trees that will help buffer the facility. Road access, a parking lot and a service building will be included in the project. Givens says the building will house the hoist for the shaft elevator, locker rooms, and possibly a conference room.

Senior Level Engineer Chris GillConstruction is planned on five acres well within the overall property, and the existing farm house will be preserved. Spectra Engineering is providing environmental analysis of the site. Respec Consulting does rock mechanic studies in the mine and is helping with the initial shaft design. Senior Level Engineer Chris Gill from the Cleveland office is heading the project, assisted by the Lansing mine's Senior Engineer Dave Plumeau.

Senior Level Engineer Chris GillConstruction is planned on five acres well within the overall property, and the existing farm house will be preserved. Spectra Engineering is providing environmental analysis of the site. Respec Consulting does rock mechanic studies in the mine and is helping with the initial shaft design. Senior Level Engineer Chris Gill from the Cleveland office is heading the project, assisted by the Lansing mine's Senior Engineer Dave Plumeau."I think we can put something together here that hopefully you will never notice," Givens said.

Residents were generally grateful for what is planned to be the first of several informational meetings, but they expressed some fears about noise, additional traffic, and property values.

"The rumor was always that it is an emergency exit and ventilation shaft," says Daniel Eikel, whose property is near the proposed site. "What they presented actually shows a 5 acre construction zone with a 70-90 ft tower, office buildings, 50 lot parking area etc.–so they really want to move the whole operation up here. With that kind of industry around, properties in the neighborhood will easily lose 20-50 % of their market value. That’s not what I signed up for when I purchased a property in a residential/agriculture district of Lansing."

Photographs overlaid with drawings of the shaft illustrate how little of the new facility will be visible

Photographs overlaid with drawings of the shaft illustrate how little of the new facility will be visibleEikel blames the town for zoning that he says is bending over backwards to find ways to get this industry approved in the RA district, and says he hopes there is a way to legally stop the project, but Givens says the project is 'allowed use' in established Lansing zoning law.

A web site has been established to explain the shaft project. Givens says the company intends to update it regularly as more information becomes available, and an FAQ will be maintained with answers to questions neighbors ask.

"Good fences, lots of trees, open spaces make for good neighbors, and we want to be a good neighbor," Givens said. "That's part of what we're doing. We bought a big buffer. As big pieces of the project arise we'll invite you back to make sure we're doing what we said we're going to do and that we've been a good neighbor."

v8i40