- By Dan Veaner

- Around Town

Print

Print  Cargill Deicing Technology invited Lansing residents to listen to a mine shaft Monday. The residents are neighbors of a potential new shaft planned for a property off of Ridge Road (NY Route 34B) near Sweazey Road. At an earlier meeting residents expressed concerns about noise, traffic, and the facility's impact on their property values. To address one of those concerns, Mine Manager Russ givens said he wanted residents to have a chance to experience the noise factor first hand.

Cargill Deicing Technology invited Lansing residents to listen to a mine shaft Monday. The residents are neighbors of a potential new shaft planned for a property off of Ridge Road (NY Route 34B) near Sweazey Road. At an earlier meeting residents expressed concerns about noise, traffic, and the facility's impact on their property values. To address one of those concerns, Mine Manager Russ givens said he wanted residents to have a chance to experience the noise factor first hand."They will be able to hear and feel what an air shaft sounds like, or doesn't sound like, for that matter," he said.

| Related Articles: A Look at the Mine New Mine Shaft Planned | ||

The salt will continue to be brought aboveground via shaft #1 at Portland Point. Givens says it would cost millions of dollars to duplicate or relocate salt processing facilities both underground and above ground, including a multi-story salt screening plant below ground that processes the salt to a size suitable for winter road salting before conveyor belts transport it to the shaft. It is then brought to the surface and stored in an enormous pile that looks like a white quarry.

Residents stand near a mine shaft to experience first hand how loud - or not so loud - it is

Residents stand near a mine shaft to experience first hand how loud - or not so loud - it isNeighbors met Monday in a tent in a parking lot just uphill from Shaft #3, which is similar in capacity to the one planned for the more northern location. Air flow sound from the shaft was not noticeable until you walked down the hill and approached the shaft. The beeping backup alarms from forklifts were much louder, and loudest was a buzzer that sounded to warn that the elevator was about to descend into the mine.

Givens says there is little air flow sound because the circulating fans are all in the mine, 2,300 below, pointed away from the shaft. on the surface you don't hear any mechanical sound from the fans, though when standing close to the shaft there is a whooshing sound. The new facility is planned on five acres of a 57 acre plot, so it is unlikely that neighbors would hear any air flow sound at all.

The elevator in Shaft #3 has a lowe section about 7 feet high, and an upper compartment around 25 feet tall that allows equipment up to 22 feet to be lowered into the mine. In this picture a large crate is being loaded into the lower section.

The elevator in Shaft #3 has a lowe section about 7 feet high, and an upper compartment around 25 feet tall that allows equipment up to 22 feet to be lowered into the mine. In this picture a large crate is being loaded into the lower section.But Givens notes that backup alarms on fork lifts may be audible. He says that while the mechanics of a mine shaft don't vary much, there are several design choices. He says he is hoping to have funding to build a shaft enclosed inside a building. The headframe, the framework that houses the elevator and hoist, would be enclosed in a tall building surrounded by a one-story building in which equipment would be stored and loaded into the shaft elevator.

"That is a model that we're looking very hard at, as opposed to an open-framed structure like we have here," he says. "Because it is inside a building, if we put materials on and off with a fork lift you won't hear that backup alarm. These things come in all shapes and sizes. Our equivalent shaft at our Cleveland operation is nothing more than a 20 foot by 20 foot by hundred foot tall building. It fits all in one piece and the hoist is mounted on top of the frame. It's built more like a conventional elevator in an office building."

The new shaft will be 2,500 feet deep, connecting to a new 4,000 foot long connecting tunnel that will take two years to mine through to the shaft location. Company representatives estimate the headframe will tower about 75 feet above ground. The company hopes to be able to use it to bring air, electricity, personnel, and equipment to the mine.

"We hope that we can build a shaft from which we can lower supplies and materials," Givens says. "Right now the only thing that is in the scope is an emergency hoist, which is smaller and we wouldn't use it for that. It's too early in the project to tell what we're going to be able to get funded. Assuming we can get what we want, then we would have a shaft with the same capability as shaft #3, and that would be able to lower all the supplies we use for mining up north."

Before a shaft can be built a test hole must be drilled to determine what kind of geology the company will be drilling through. Senior Engineer Dave Plumeau says initial bids were too high and the company is looking for a more economical way to drill the hole to gather the information they need.

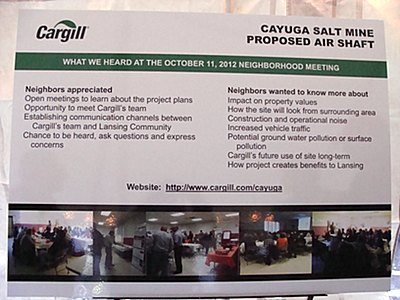

Cargill posted a list of concerns neighbors raised in an earlier meeting in October, and a Web site address where the questions about the new shaft will eventually be aggregated and answered. One of the major concerns is additional traffic. But Givens says that he doesn't think the new shaft will change the current volume of traffic. He says only two semi-trailer trucks per day typically deliver equipment, while other deliveries are by smaller Fedex and UPS trucks that deliver to homes and businesses.

If all goes according to plan, the company hopes the new shaft, including the surface facility, will be completed some time in 2015.

v8i43